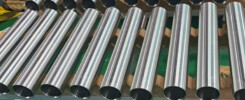

SAE1045 induction hardened rods are the strong, durable solution for high-stress applications. As experienced producers and manufacturer of induction hardened rods , DATONG HYDRAULIC specializing in heat-treated steel solutions, we explain why these rods outperform traditional options and how they can elevate your machinery’s performance.

1045 induction hardened rods are engineered for industries where wear resistance, hardness, and reliability are non-negotiable. The process combines: Precision Induction Hardening: A controlled heating and quenching method that creates a super-hard outer layer while keeping the core tough and ductile.

1045 Steel Composition: High-carbon steel (0.45% carbon content) for exceptional tensile strength (up to 62 HRC) and durability in heavy-duty environments.

Why Engineers and Buyers Choose 1045 Induction Hardened Rods

1. Superior Wear & Impact Resistance

The hardened surface withstands abrasion, corrosion, and high-pressure impacts, reducing wear and tear in machinery. Ideal for parts like axles, shafts, or gearboxes.

2. Cost-Effective Production

Induction hardening targets only the surface, saving energy compared to full-hardening methods. Plus, our rods come pre-machined to tight tolerances, cutting your setup time.

3. Consistent Quality, Every Time

Our automated induction hardening systems guarantee uniform hardness (HRC 50-60) and dimensional accuracy. No weak spots, no surprises.

4. Custom Solutions for Your Needs

Need specific diameters (e.g., 10mm–200mm), lengths, or surface finishes? We adapt to your specs. Whether you need plain rods, threaded ends, or coated variants, we’ve got the tools.

5. Global Compliance & Standards

All rods meet ASTM A29, AISI 1045, and ISO 9001 standards. We also provide test reports (hardness, tensile strength, non-destructive testing) to ensure compliance with your industry regulations.

How to Order

- Tell Us Your Specs: Share dimensions, quantity, and special requirements (e.g., chrome plating, anodizing).

- Get a Fast Quote: We’ll confirm feasibility and timelines within 24 hours.

- Approve Prototypes: Test samples before full production to ensure perfection.

- Global Shipping: We deliver to Europe, North America, Asia, and beyond.